Synchronization Panels are mainly designed and used to meet power system requirements. They will

operate on an automatic mains failure system, so that when the main supply is interrupted in one or

all phases (after an adjustable delay period) the generator sets will kick-off together. After an

initial warm-up period (adjustable) the generators will synchronize with each other through

motorized circuit breakers or contactors onto a common bus-bar. Then the motorized changeover switch

will be closed and the load will be connected to the main distribution box.

The load share units continuously monitor the load. During low demand situations one or two

generators will be shut down to save on fuel consumption. Once the demand rises the second and third

generator will be restarted, synchronized and reconnected to the load. When the AMF control unit

detects that the main supply has been restored, an adjustable observation period is activated before

the main supply is reconnected. A cool down period will then follow, after which the generator sets

will be shut down.

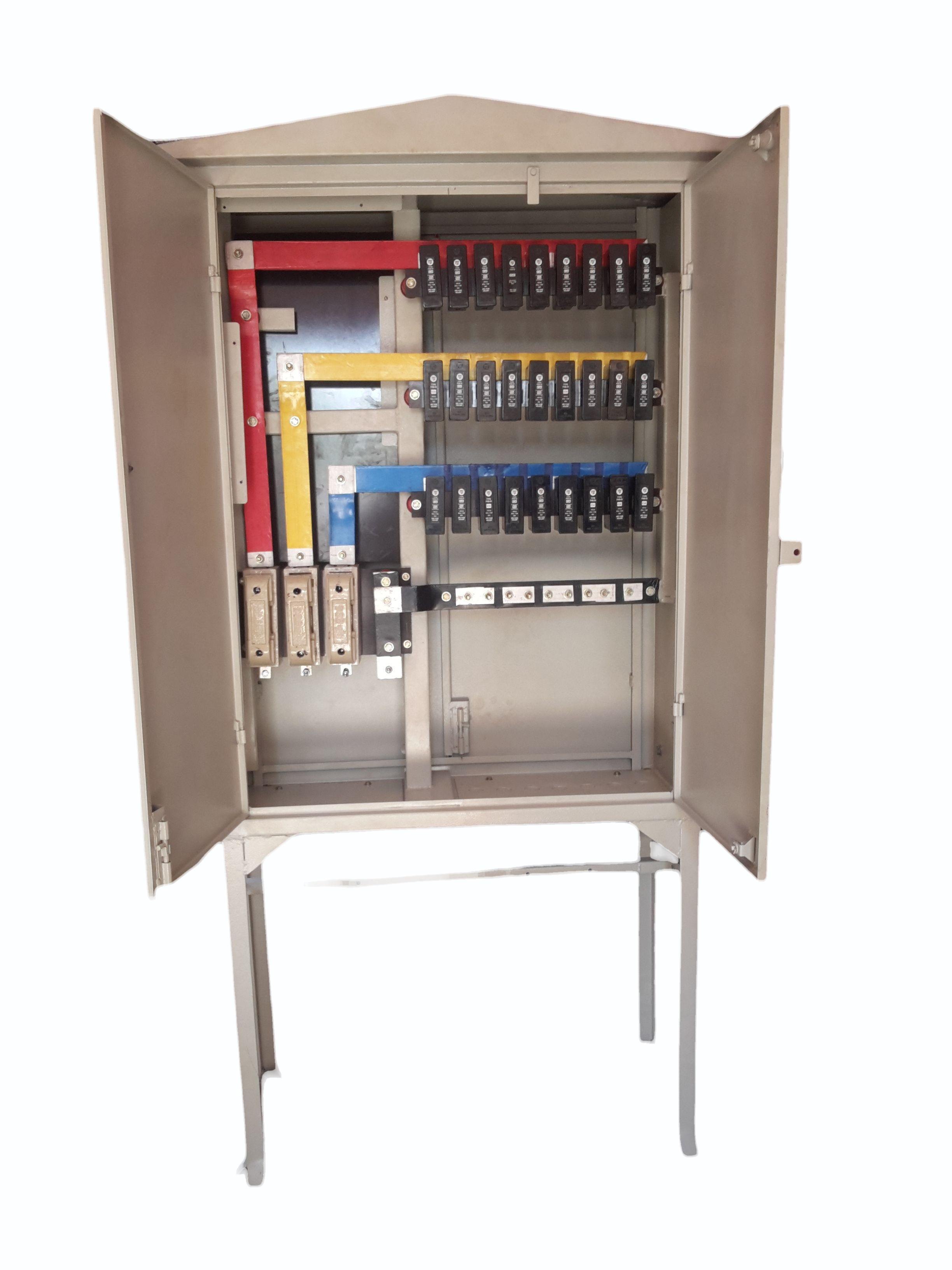

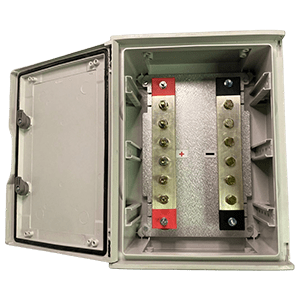

Our high-quality ranges of synchronizing panels are available with capacities and are fabricated by

our engineers using premium quality electrical components including copper bus bar, insulations,

wires/cable, PVC, channels, transformers, meters and switches.